rockwell hardness test lab manual pdf|hardness test lab report pdf : bespoke Rockwell hardness test is the rapidest, easiest and most economic testing method in mechanical performance tests. Featuring high efficiency and easy-to-operate, the hardness values can be . Viviwinkler (@viviwinkleroficial) Oficial | TikTok. viviwinkleroficial. Viviwinkler. Seguir. 76 Seguindo. 5.4M Seguidores. 49.4M Curtidas. BRABA 🏆 . www.sotembraba.com.br. .

{plog:ftitle_list}

WEB5 de jul. de 2021 · This video is designed to help you type yourself. Test: https://sakinorva.net/functionsPacket: .

rockwell hardness testing procedure pdf

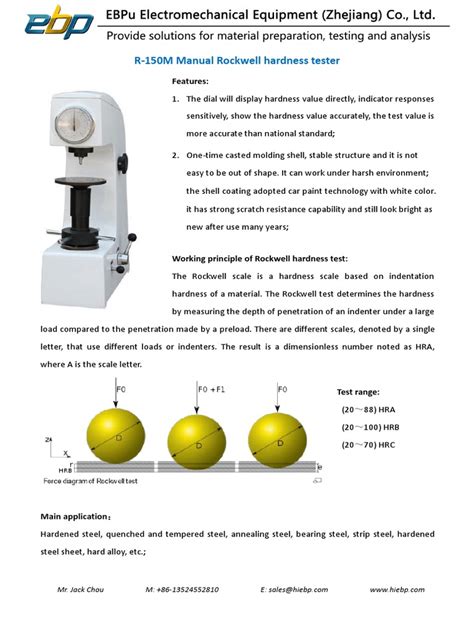

The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inverselyTableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

Rockwell hardness test is the rapidest, easiest and most economic testing method in mechanical performance tests. Featuring high efficiency and easy-to-operate, the hardness values can be .

spigen ultra hybrid drop test iphone 6

The Rockwell hardness is derived from the measurement of the depth of the impression EP = Depth of penetration due to Minor load of 98.07 N. Ea = Increase in depth of .In Rockwell hardness test, a standard load (based on type of material) is applied through a standard indentor (cone or ball) for a specified duration, on the material & depth of impression .Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .This document contains test procedures for quantitative and comparative analysis of Rockwell hardness on metal evidence. To evaluate a surface hardness gradient (e.g., due to carburizing

A hardness test can be conducted on Brinell hardness testing machine, Rockwell hardness machine or Vicker hardness testing machine. The specimen may be a cylinder, cube, thick or .Hardness Test 1/5 LAB 2 HARDNESS TEST OBJECTIVES (1) Make Brinell, Vickers and Rockwell hardness measurements on different materials specimens. (2) Compare the .

The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In .Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing

the surface of the test piece is approximately 1/8” to 1/16” from the tip of the indenter. 3. Press the StArt key to initiate a test cycle 4. the display will count down to “0” (See keypad section of manual to adjust time-at-load). 5. When the test is complete, the .www.iqualitrol.com, [email protected] 1 Service Call: +86‐13711988687 HR‐150A Rockwell Hardness Tester Operation ManualRockwell hardness test is to apply diamond cone indenter (see Fig-2) or steel ball indenter (see Fig-3) to the specimen surface in two steps as shown in Fig-1, which shall be retained for a certain period of time, and measure the residual indentation depth under preliminary test force after the main test force is removed. The Rockwell hardness is PDF | This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test | Find, read and cite all the research you need on ResearchGate

Test Setup: Rockwell Hardness Testing Machine. Indenters: i) For Rockwell – B Test: Steel ball indenter of diameter (1/16)th inch. ii) For Rockwell – C Test: Rockwell diamond cone of vertex angle 120o and tip radius 0.2 mm. Standard Loads: Sl. No. Material For Rockwell – B Test Load, kgf For Rockwell – C Test Load, kgf 1.the test result will be displayed. If the test result exceeds a tolerance setting, the test result will be preceded by a blinking “H” or “L” for high or low result. 6. To take a second test, the handwheel must be turned counter-clockwise to lower the in-denter from the test specimen before another test can be taken.

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .

ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for .

Rockwell hardness testing machine series Versatile smart models 3 models to suit practically every application Features Specifications External dimensions (512) 434 65 218 352.4 162 150 13 780 . Manual Maximum specimen dimensions Height 180 mm (100 mm if the cover is attached), depth 165 mm (from indenter axis to the frame)7. SPECIFICATION OF HARDNESS TESTING MACHINE AND INDENTERS A hardness test can be conducted on Brinell hardness testing machine, Rockwell hardness machine or Vicker hardness testing machine. The specimen may be a cylinder, cube, thick or thin metallic sheet. A Rockwell hardness testing machine along with the specimen is shown in Figure 2.EXP.NO.1: ROCKWELL HARDNESS TEST. AIM: To study the Rockwell hardness test and determine the hardness number of the given specimen. APPARATES: Rockwell hardness testing machine. PROCEDURE: 1) Place the specimen on the anvil so that its surface will be normal to the direction of the applied load.Page 6 of 13 Results Rockwell Scale C Scale B Scale A 150kgf 100kgf 60kgf Hardness Testing Rockwell Testing Scale C set to 150Kg Speciemen used in test Size of indent Z-specimen C10 Z4-specimen C34 Hardness Testing Rockwell Testing Scale B set to 100Kg Speciemen used in test Size of indent Z-specimen B95.5 Source of errors • Impact of .

The selection of test force is automatically adjusted once you select your hardness scale. There are three test forces of 60kgf(588.4N), 100kgf(980.7N) and 150kgf(1471N) for Rockwell hardness measurement, and also three test forces of 15kgf(147.1N), 30kgf(294.2N) and 45kgf(441.3N) for Rockwell superficial hardness measurement.Rockwell Hardness Testers Manual; Indentron Hardness Testers - 300: Manual in English: Indentron Hardness Testers - 400 : Manual in English: . Manual: DataView for Hardness Testing Manual in English: C.A.M.S. for Microhardness Testing Manual in English: JOIN THE CONVERSATION. INDUSTRIES .LABORATORY MANUAL B.Tech. Semester-IV STRENGTH OF MATERIAL Subject code: LC-ME-214G Prepared by: Checked by: Approved by: Mr. Rajesh Mattoo Mrs. Neha Chauhan Name : Prof. (Dr.) Isha Malhotra . To study the Rockwell hardness testing machine & perform the Rockwell hardness test. 3. To study the Vickers hardness testing machine & perform the .

Test Cycle Type Motorized (manual preload, auto trip, auto-brake) Motorized (manual preload, manual trip) . using Wilson Standards laboratory blocks and indenters. . For more information call 1-800-695-4273 or 1-781-575-6000 Wilson® Instruments Rockwell 500 Hardness Testers – Technical Specifications www.wilsoninstruments.com . Title .3. Low-load & micro hardness testing machines − the DuraScan Series 6 4. Universal hardness testing machines − the DuraVision Series 8 5. DuraJet Rockwell hardness testing machine – flexible & versatile 10 6. ZHR Rockwell hardness tester 12 7. ecos™ III – The most efficient hardness testing software 14 8.

STRENGTH OF MATERIALS LABORATORY MANUAL (CE) (II B.TECH CIVIL 1st SEM) . 2. Double Shear Test. 8 3. Brinell/Rockwell hardness Test. 10 4. Young’s Modulus of given specimen. 14 5. Charpy/Izod Impact Test. 17 6. Torsion Test. 21 7. Test on springs. . Brinell's hardness testing machine, microscope and specimen LABORATORY MANUAL FOR HARDNESS TEST Department of Materials Science and Engineering, African University of Science and Technology, Abuja. A) ROCKWELL HARDNESS TEST (I) Aim: .

The Starrett 3814 accurately measures hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120 diamond indenter in the C-scale (HRC 20-70). Soft materials are tested using a 1/16" . this manual prior to .According to the thickness of the test piece increase, the diameter of the indentor and force are changed. A hardness test can be conducted on Brinell testing m/c, Rockwell hardness m/c or vicker testing m/c. the specimen may be a cylinder, cube, thick or thin metallic sheet.

Measurement of Hardness Using Rockwell Hardness Tester Objective: To introduce the students to the concept of hardness, various methods of testing hardness, Rockwell hardness testing procedure and then to find the hardness of metal virtually by selecting an appropriate scale. The navigation: Below is the screen shot of the virtual lab screen .

4 To determine the Impact toughness (strain energy) through Izod test and Charpy test. 12 5 To determine the Impact toughness (strain energy) through and Charpy test. 15 6 To determine the hardness of the given specimen using Brinell hardness test 17 7 To determine the hardness the Hardness of the given Specimen using Rockwell hardness test. 20TWIN Rockwell Hardness Tester Model No. 3815 Operation Manual Technical Support Tel: (201)962-8352 . E. 5 Rockwell Test Blocks 1. Two each, HRC 2. One each, HRB 3. Two each, HRN 4. One each, HRT . Operating Instructions & Parts Manual Page 9 ) (HRC) Hardness .Each hardness test method, or scale, is defined with a particular type of indenter, a specified . Refer to Mechanics of Material Laboratory manual for detail information. Summary of Theory: Vickers hardness test requires a diamond pyramid indenter with an included angle of 136o. This technique is also called a diamond pyramid hardness test .Rockwell Hardness Testing System NI-500 Series User Manual Newage hardness testing 820 Pennsylvania Blvd., Feasterville PA 19053 USA Tel: 215-355-6900 • Fax: 215-354-1803 [email protected] • www.hardnesstesters.com P/N MA-225 Rev. 00

spigen ultra hybrid drop test iphone 7

WindGURU weather forecast for Batan and surrounding areas.

rockwell hardness test lab manual pdf|hardness test lab report pdf